Flywheel housing

Baoding Guokun is the professional casting factory and machine shop with 80 staff, producing various customized machined casting products as per customer’s drawings. We have equipped with investment casting, sand casting process and die casting, various CNC machinery and all testing machinery, such as spectrograph, hardness tester, Metallographic analyzer, CMM, UT, X-ray test, MT, PT, etc.

Baoding Guokun can produce various flywheel housing as per your drawings. Flywheel housings are often made from aluminum or cast iron composite material. They are designed to match the engine and vehicle's structure, making them easier to install and more compatible with other components. Flywheel housings also offer different mounting options for different engine types, so they can be used in a wide range of vehicles.

|

Product Name |

Flywheel housing |

|

Material |

Cast iron, cast aluminum |

|

HS Code |

840999 |

|

Application |

Engine, truck parts The flywheel housing is solid and sits on the outside of the Flywheel. The flywheels are the part of the engine that spins and provides power to the alternator |

|

Unit Weight |

0.5kg~300kg |

Flywheel housing functions:

If you need flywheel housing, flywheel housing cover, aftermarket flywheel housing for engine truck, front flywheel housing, rear flywheel housing, bell housings, engine flywheel housing, heavy duty truck flywheel housing, caterpillar flywheel housing, please feel free to contact gina@guokuncasting.com to get a quote.

Drum Brake

Baoding Guokun is the professional casting factory and machine shop with 80 staff, producing various customized machined casting products as per customer’s drawings. We have equipped with investment casting and sand casting process, various CNC machinery and all testing machinery, such as spectrograph, hardness tester, Metallographic analyzer, CMM, UT, X-ray test, MT, PT, etc.

The drum brake most frequently used in heavy commercial vehicles. Baoding Guokun can offer brake drums for all kind of vehicles. Material is strictly controlled and brake drum is well balanced to avoid vibration.

|

Product Name |

Drum Brake |

|

Material |

Cast iron, grey iron, ductile iron, such as GG20, HT250, etc |

|

Car Model |

Semi-trailer, truck, etc |

|

Color |

Black or as per your required colors |

|

Unit Weight |

0.5kg~300kg |

The main material information of grey iron are as follows:

A brake drum is a cylinder attached to a car's wheel. When the brake pedal is pressed, the brake shoes inside the brake drum are pushed outwards to slow the vehicle down.

If you need import drum brake, trailer brake drum, car drum brake, rear drum brake, semi trailer brake drum, brake shoes, wheel end parts, heavy duty truck drum brake, heavy duty trailer brake drum, GG20 brake drum, trailer balanced brake drum, outboard mount balanced brake drum, oil-grooved balanced brake drum, centrifuse balanced brake drum, fully machined balanced brake drum, brake drum replacement, brake drum backing plate, balancing brake drum, brake disc, brake drum cover, car brake drum, crane brake drum, trailer brake drum replacement, semi trailer drum brake, drum brake car trailer, cast iron brake drum, gray iron brake drum, metal brake drum, casting brake drum, casted brake drum, please feel free to contact gina@guokuncasting.com

WCB vs. WCC

Both WCB and WCC are grades of ASTM A216 cast steels. ASTM A216 has three grading levels: A, B, and C, with C being the highest or “best.” From A to C, the manganese content and yield strength increase. WCC, while similar to WCB, has different chemical and physical requirements.

WCC contains the exact maximum percentages of Residual Elements; however, for every 0.1% reduction of Carbon below the maximum (0.30%), the Manganese can be increased by .04% without passing a maximum of 1.40% (instead of the 1.28% for WCB). It comprises the same elements as WCB, except with slighter less carbon and a higher maximum percentage of manganese.

WCC has a higher pressure and temperature resistance than WCB because WCC has a higher yield strength and manganese content. Adding manganese to the steel can increase hardness and make it more durable. WCC is considered superior to WCB as it is stronger and better for casting due to its high density and binding.

Because of these attributes, WCC tends to be more expensive. While it is considered better than WCB, the small increase in physical properties usually doesn’t justify the higher price. As such, WCB valves see much more frequent use in industry.

What is penetrant testing (PT)?

Dye Penetrant Inspection (DPI) is widely used to detect surface breaking flaws. This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities.

The test works by applying a visible dye to the surface and letting it sit for several minutes to penetrate cracks and imperfections.

Then excess dye is cleaned away and a developer is applied to pull remaining dye from the crack and highlight areas of concern.

The developer dries into a white powder, and red indications will appear on the surface where the penetrant has gone into a cavity or crack.

How to do the dye penetrant?

| Here are the steps for a dye penetrant test: | ||

| Step 1 | Clean | Coat the part to be inspected with cleaner or remover. Allow the cleaner to dissolve dirt or film. Wipe dry with a clean cloth. Repeat if necessary. |

| Step 2 | Apply penetrant | Spray or brush the part to be inspected with penetrant. Allow the penetrant to remain on the part for 10-30 minutes. |

| Step 3 | Clean way excess dye | Excess dye is cleaned away. |

| Step 4 | Apply developer | A developer is applied to pull remaining dye from the crack to highlight areas of concern. |

Dye penetrant testing is commonly used to inspect the surfaces of non-porous assets made out of ceramics, plastics, and metals, such as welds, castings, forgings, plates, bars, and pipes.

Advantages of dye penetrant inspection include:

Baoding Guokun, is a professional casting factory, mainly produding and exporting various metal castings in steel, iron, aluminum, bronze, etc. So the standard we used for PT is EN 1371-1, This European Standard specifies a liquid penetrant testing method for castings produced in conventional sand moulds, by gravity and low-pressure die casting, except for investment castings and high-pressure die castings.

This European Standard applies to all cast metals, except copper-tin and/or copper-tin-lead alloy castings, where copper is the major constituent.

I listed some standards as follows:

ASTM A216 WCA

ASTM A216/A216M-18 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-temperature Service.

ASTM A216 has three grading levels: A, B and C. That is, ASTM A216 WCA, ASTM A216 WCB, and ASTM A216 WCC. The WC signifies that the carbon steel is weldable cast. The A, B and C signify the quality of steel, with C being the highest or “best”. From A to C, the manganese content and yield strength increase.

Grade WCA is covered by ASTM A216 standard, which specification covers carbon steel castings for valves, fittings, flanges and other pressure-containing parts for high temperature service and the quality required for assembly with other castings or wrought steel parts by fusion welding.

ASTM A216 Grade WCC casting chemical composition and mechanical properties:

|

ASTM A 216 WCC |

|

|

Chemical Composition |

C: 0.25 Max Mn: 0.70 Max Si:0.60 Max S: 0.045 Max P: 0.040 Max Cu: 0.30 Max Ni: 0.50 Max Cr:0.50 Max Mo: 0.20 Max V:0.03 Max |

|

Mechanical Properties |

Tensile strength: 60-85 KSI (415-585 MPa) Yield Strength: 30 ksi (250 Mpa) Min Elongation: 24% Min Reduction of area: 35% Min Hardness: 137 HB min |

Baoding Guokun is an ISO 9001-2008 registered iron and steel foundry and supplier of high-quality customized castings in carbon steel, alloy steel, stainless steel, gray iron, ductile iron, aluminum and brass. Our machined casting parts are mainly used for power, electrical, mining, agriculture, railway, truck, oil & gas, valve and pump, marine, etc.

It is our mission to provide flexible, cost-effective solutions for our customer on time, every time while maintaining the highest standards of quality. If you have any inquiry of various casting & forging parts, please contact us vis gina@guokuncasting.com or gina.guokun@gmail.com to get a quote.

ASTM A216 WCA

ASTM A216/A216M-18 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-temperature Service.

ASTM A216 has three grading levels: A, B and C. That is, ASTM A216 WCA, ASTM A216 WCB, and ASTM A216 WCC. The WC signifies that the carbon steel is weldable cast. The A, B and C signify the quality of steel, with C being the highest or “best”. From A to C, the manganese content and yield strength increase.

Grade WCA is covered by ASTM A216 standard, which specification covers carbon steel castings for valves, fittings, flanges and other pressure-containing parts for high temperature service and the quality required for assembly with other castings or wrought steel parts by fusion welding.

ASTM A216 Grade WCC casting chemical composition and mechanical properties:

|

ASTM A 216 WCA |

|

|

Chemical Composition |

C: 0.25 Max Mn: 0.70 Max Si:0.60 Max S: 0.045 Max P: 0.040 Max Cu: 0.30 Max Ni: 0.50 Max Cr:0.50 Max Mo: 0.20 Max V:0.03 Max |

|

Mechanical Properties |

Tensile strength: 60-85 KSI (415-585 MPa) Yield Strength: 30 ksi (250 Mpa) Min Elongation: 24% Min Reduction of area: 35% Min Hardness: 137 HB min |

Baoding Guokun is an ISO 9001-2008 registered iron and steel foundry and supplier of high-quality customized castings in carbon steel, alloy steel, stainless steel, gray iron, ductile iron, aluminum and brass. Our machined casting parts are mainly used for power, electrical, mining, agriculture, railway, truck, oil & gas, valve and pump, marine, etc.

It is our mission to provide flexible, cost-effective solutions for our customer on time, every time while maintaining the highest standards of quality. If you have any inquiry of various casting & forging parts, please contact us vis gina@guokuncasting.com or gina.guokun@gmail.com to get a quote.

ASTM A216 WCC

ASTM A216/A216M-18 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-temperature Service.

ASTM A216 has three grading levels: A, B and C. That is, ASTM A216 WCA, ASTM A216 WCB, and ASTM A216 WCC. The WC signifies that the carbon steel is weldable cast. The A, B and C signify the quality of steel, with C being the highest or “best”. From A to C, the manganese content and yield strength increase.

Grade WCC is covered by ASTM A216 standard, which specification covers carbon steel castings for valves, fittings, flanges and other pressure-containing parts for high temperature service and the quality required for assembly with other castings or wrought steel parts by fusion welding.

ASTM A216 Grade WCC casting chemical composition and mechanical properties:

|

ASTM A 216 WCC |

|

|

Chemical Composition |

C: 0.25 Max Mn: 1.20 Max Si:0.60 Max S: 0.045 Max P: 0.040 Max Cu: 0.30 Max Ni: 0.50 Max Cr:0.50 Max Mo: 0.20 Max V:0.03 Max |

|

Mechanical Properties |

Tensile strength: 70-95 KSI (485-655 MPa) Yield Strength: 40 ksi (275 Mpa) Min Elongation: 22% Min Reduction of area: 35% Min Hardness: 137 HB min |

Baoding Guokun is an ISO 9001-2008 registered iron and steel foundry and supplier of high-quality customized castings in carbon steel, alloy steel, stainless steel, gray iron, ductile iron, aluminum and brass. Our machined casting parts are mainly used for power, electrical, mining, agriculture, railway, truck, oil & gas, valve and pump, marine, etc.

It is our mission to provide flexible, cost-effective solutions for our customer on time, every time while maintaining the highest standards of quality. If you have any inquiry of various casting & forging parts, please contact us vis gina@guokuncasting.com or gina.guokun@gmail.com to get a competitive prices.

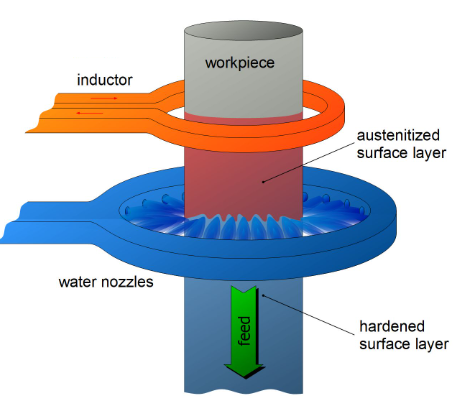

Induction hardening

Induction hardening is a type of heat treatment process in which a metal part is induction-heated and then quenched. It is a process used for the surface hardening of steel and other alloy components.

Induction hardening can increase the mechanical properties of ferrous components in a specific area. Baoding Guokun typically apply the induction hardening process to the powertrain, suspension, engine components, casting, forging and stampings, such as gears, shafts, axles, cam lobes, etc

Benefits of induction hardening

Baoding Guokun Machinery Co., Ltd and Baoding Guokun Export and Import Trading Co., Ltd are located in Baoding city, Hebei province, China. Our sand casting factory occupies a total area of 30,000 square meters, which have casting foundry workshop, grinding, sandblasting and precision machining shop, laboratory and warehouse. Baoding Guokun has equipped with 4 sets medium-frequency electric furnaces, 15 sets automatic shell core machinery, automatic sand casting molding line, 7 sets CNC machinery, 20 sets CNC Lathe, and the complete quality inspection devices for mechanical testing and chemical analysis, including tensile strength, hardness tester, metallographic inspection, spectrometer, ultrasonic testing and special testing devices. Before shipping, the quality reports for all inspection will be issued and mailed to our customers.

Self-hardening furan resin sand casting process

Why phosphoric acid is mostly used as a curing agent for high nitrogen furan self-hardening resins,

but seldom used as a curing agent for low nitrogen furan self-hardening resins?

This is because low nitrogen and high furfuryl alcohol resin, when acid is used as curing agent, the hardening speed is slow,

the demolding time is long, and the strength is very low.

The high nitrogen low furfuryl alcohol resin uses phosphoric acid as the curing agent to obtain the required curing speed.

In addition, the high nitrogen low furfuryl alcohol resin uses phosphoric acid as a catalyst to obtain good final strength.

The reason for this result is mainly due to the poor miscibility of phosphoric acid and furfuryl alcohol and high affinity with water,

which makes it difficult for the water contained in the resin and the catalyst and the water produced in the resin polycondensation reaction to diffuse.

And discharged, with phosphoric acid as the core.

Water droplets remain in the resin film and destroy the compactness of the resin film, so the strength is low.

The high nitrogen resin has good mutual solubility with water, and various waters are not easy to be concentrated into droplets with phosphoric acid as the core.

The resin film has a good structure and high strength.

Baoding Guokun specialized in sand molded casting, green sand casting, resin sand casting, precoated sand casting, shell molding casting with grey iron, ductile iron, cast iron, cast steel, cast aluminum, bronze, brass, copper with high quality and competitive prices and high quality. All of our customized metal castings are manufactured accoridng to custoer's requirements, drawings, design or samples.

EN-GJL-150 or EN 1691 GG 15 grey cast iron

EN-GJL-150 is one of grey cast iron in European standard EN 1561, it is also named as gray cast iron GG15 in standard DIN 1691 by Germany and Austria.

The Grade is equivalent with grey iron GB/T 9439-1988 HT150, ASTM A 48, class 20, JIS G5501 FC15, NFA32-101 Ft.15D, BS1452 Gr.150, ISO/R185 Gr.15 in China and other countries.

The chemical composition of GG15 gray cast iron is not standard. Baoding Guokun, the professional China casting foundry can adjust the chemical composition according to the production conditions, as long as we coouold meet the mechanical properties.

EN 1691 GG 15 Mechanical properties:

Tensile Strength: 150 Mpa min

Hardness: 150~200

Casting process for Gray iron GG15:

Shell mold casting

Sand casting

Precoated sand casting

Green sand casting

If you need custom grey iron castings for railway & train, auto parts, valve & piping, mining, heavy engineering, industrial engineering, engineering & construction, please contact tina@guokuncasting.com to get the competitive prices.